Welcome to Our Website

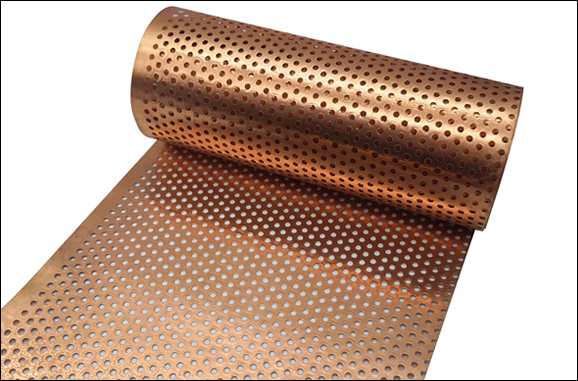

Copper perforated panels refers to a sheet or panel made of copper that has been perforated with a pattern of holes. Perforation involves creating a series of regularly spaced or custom-designed holes in the metal surface, allowing for the passage of air, light, sound, or other substances. Copper perforated panels find applications in architecture, interior design, industrial settings, and more. They are commonly used as decorative elements, facades, sunscreens, privacy screens, acoustic panels, ventilation covers, and signage.

Copper panel with the following dimensions:

- Approximate thickness 1/8 inch

- 1 each 28 1/4 inch x 28 1/4 inch and 1 each 28 1/4 inch x 13 1/4 inch

- Hole size 3/8 inch

- Distance between holes 3/8 inch. Not center to center, but the distance from end of one hole to the start of the next hole.

- Hole pattered staggered

- 1 inch margin/border on all four sides before holes start.

The specific hole pattern and size can be customized to achieve desired aesthetic effects, functionality, or performance characteristics, such as light diffusion, sound absorption, or airflow regulation.

Perforated copper sheets or panels to a solar shading canopy of about 240 sq m in size for building project.

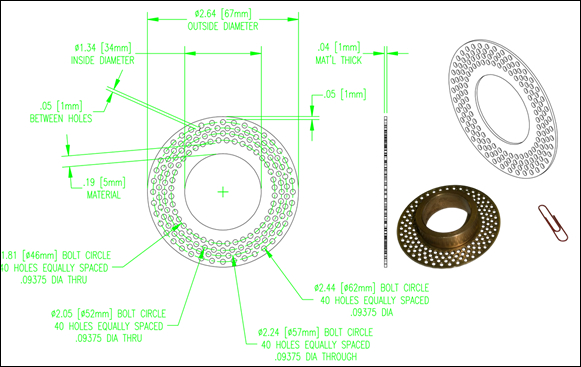

Brass is an alloy of copper and zinc, known for its strength, corrosion resistance, and conductivity. It is commonly used in applications where both durability and aesthetic appeal are important. The perforated brass filter elements are designed to allow the passage of fluids or gases while trapping or filtering out unwanted particles or contaminants. These filter elements are utilized in a wide range of industries and applications, including HVAC systems, automotive, aerospace, oil and gas, chemical processing, water treatment, and more. The size, shape, and arrangement of the perforations can be customized to meet specific filtration requirements, such as particle size, flow rate, or filtration efficiency.

Perforated Brass Filter Element like this in either a sheet style or as a round pounced out part.

The perforated brass filter elements offer several advantages. The brass material provides excellent resistance to corrosion, making it suitable for use in harsh environments. The perforations allow for efficient filtration without significantly impeding the flow of fluids or gases. Furthermore, brass has antimicrobial properties, which can be beneficial in applications where preventing bacterial growth is essential.

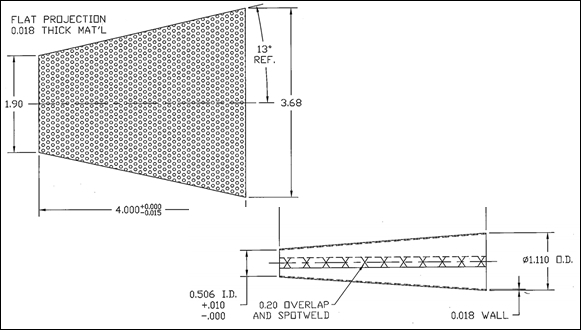

Air strainer panels are usually made of a mesh or screen material, such as copper coated or stainless steel. The mesh has a specific pore size or opening, allowing air to pass through while trapping larger particles. The mesh size can vary depending on the intended application and the level of filtration required. Common mesh sizes range from coarse to fine, with finer meshes offering higher filtration efficiency.Air strainer panel, also known as an air intake strainer panel or air filter panel, is a device used to filter and clean the air entering a ventilation or HVAC system. It is typically installed at the intake or inlet of air handling units, air conditioners, cooling towers, or other air-handling equipment. Regular cleaning or replacement of the strainer panels is important to ensure optimal airflow and filtration performance.

26 Gage (0.018") Perforated Brass as shown in the flat projection on drawing attached.

Machine will do the forming & spot welding.

Air strainer panels play a vital role in maintaining clean and efficient air intake for ventilation and HVAC systems, helping to improve indoor air quality and protect equipment from potential damage.