Welcome to Our Website

Copper alloy wire is a widely used material known for its exceptional electrical conductivity, thermal conductivity, corrosion resistance, and ductility. It finds applications in numerous industries, ranging from electrical and electronics to automotive, construction, and telecommunications. Copper alloy wire is primarily composed of copper, with the addition of various other elements to enhance specific properties. These alloying elements can include zinc, tin, nickel, phosphorus, aluminum, and silver, among others. The composition of copper alloys is carefully selected to achieve desired characteristics such as improved strength, conductivity, and corrosion resistance.

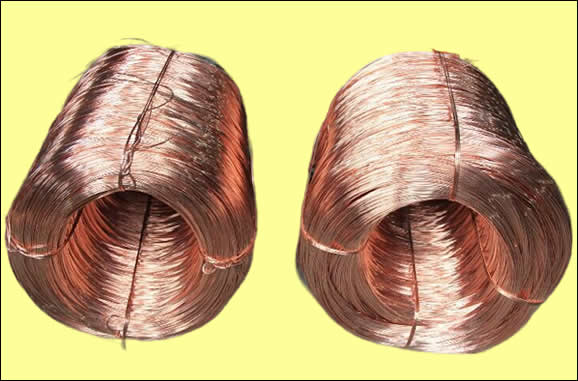

High-strength brass alloy wire, multiple sizes available customised

Materials:

Copper alloy wire is available in a wide range of compositions, each offering unique properties suitable for specific applications. Some commonly used copper alloys include:

Brass Wire: Brass is a copper-zinc alloy that exhibits excellent malleability, corrosion resistance, and electrical conductivity. It is often used in electrical connectors, springs, and fasteners.

Bronze Wire: Bronze is a copper-tin alloy known for its high strength, wear resistance, and resistance to corrosion. It finds applications in musical instruments, marine applications, and architectural elements.

Phosphor Bronze Wire: Phosphor bronze is a copper-tin alloy with the addition of phosphorus, which enhances its strength, fatigue resistance, and electrical conductivity. It is commonly used in springs, electrical contacts, and connectors.

Nickel Silver Wire: Nickel silver, also known as German silver, is a copper-nickel-zinc alloy that offers excellent resistance to corrosion, high strength, and good electrical conductivity. It is used in jewelry, musical instruments, and electrical connectors.

Diameter Size, Colors, and Length:

Copper alloy wire is available in a wide range of diameter sizes, colors, and lengths to accommodate different applications. The diameter sizes typically range from a few millimeters to a fraction of a millimeter, depending on the specific requirements. Common colors of copper alloy wire include shades of gold, red, and bronze, depending on the alloy composition. Lengths can vary based on customer specifications, with spools or coils containing anywhere from a few meters to several kilometers of wire.

Characteristics:

Copper alloy wire possesses several characteristics that make it an ideal choice for various applications:

High Conductivity: Copper alloy wire exhibits excellent electrical conductivity, making it suitable for applications where efficient current transfer is required.

Thermal Conductivity: Copper alloys have exceptional thermal conductivity, allowing them to efficiently transfer heat in applications such as heat exchangers and electrical motor windings.

Corrosion Resistance: Many copper alloys offer good resistance to corrosion, ensuring their longevity and reliability in harsh environments.

Ductility and Formability: Copper alloy wire is highly ductile and can be easily formed into various shapes, making it versatile for different manufacturing processes.

Surface Treatment and Coating:

To enhance the performance and appearance of copper alloy wire, various surface treatments and coatings can be applied. Common surface treatments include tin plating, nickel plating, silver plating, and gold plating. These treatments provide improved solderability, wear resistance, and protection against corrosion.

Popular Styles:

Copper alloy wire is available in various styles to meet specific application requirements. Some popular styles include:

Solid Round Wire: This is the most common style of copper alloy wire, available in different diameters for various applications.

Flat Wire: Copper alloy wire can be flattened to create a flat wire style, suitable for specific applications such as electrical connectors and springs.

Square Wire: Square-shaped copper alloy wire offers increased strength and stability, often used in mechanical components and jewelry making.

Packaging Rolls:

Copper alloy wire is typically packaged in rolls, which can vary in size depending on the length and diameter of the wire. The rolls are commonly made of plastic or cardboard and are designed to protect the wire from damage during transportation and storage. The packaging may include labels indicating the alloy type, diameter, length, and other relevant information for easy identification and handling.

Copper alloy wire is a versatile material with a wide range of applications across various industries. Its excellent electrical and thermal conductivity, corrosion resistance, and ductility make it an ideal choice for numerous manufacturing processes. With its diverse composition, surface treatment options, and packaging flexibility, copper alloy wire continues to provide economic benefits and solutions to meet the evolving needs of different industries.