Welcome to Our Website

The copper alloy hexagonal bar is a versatile material with excellent mechanical, electrical, and thermal properties. Its unique shape and composition make it suitable for a wide range of applications in various industries. With its high tensile strength, ductility, anti-magnetic properties, and corrosion resistance, this hexagonal bar continues to be a preferred choice for engineers, designers, and manufacturers across different sectors.

Copper alloys have long been prized for their excellent mechanical and electrical properties, making them vital materials in various industries. One particular form of these alloys is the hexagonal bar, which offers unique advantages due to its shape and composition.

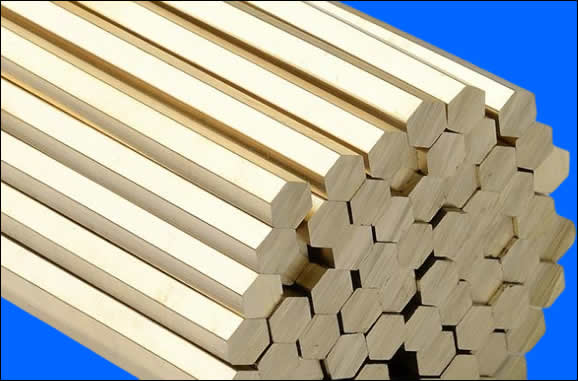

Hexagonl CuZn30 CuZn35 brass bar

Classification and Specifications

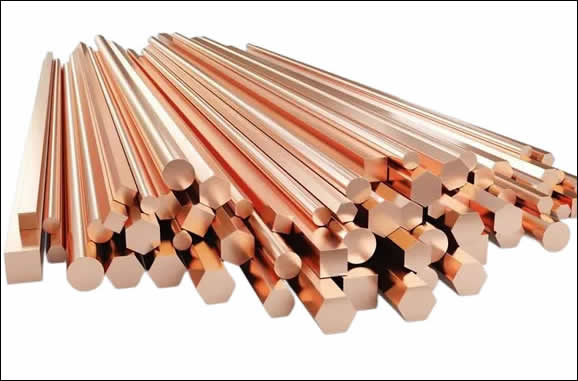

The copper alloy hexagonal bar is classified as a non-ferrous metal product and falls under the broader category of copper alloys. It is commonly manufactured using a combination of copper, zinc, and other elements to enhance specific properties. The hexagonal shape of the bar offers advantages in terms of strength, ease of handling, and versatility in applications.

The specifications of the copper alloy hexagonal bar may vary depending on the manufacturer and customer requirements. However, typical specifications include dimensions such as width on the opposite side, width on the opposite side, and length. These dimensions can range from a few millimeters to several inches, catering to a wide range of applications.

Chemical Composition

The chemical composition of the copper alloy hexagonal bar is crucial in determining its properties and performance. The primary elements found in these alloys include copper and zinc, which form the base of the material. Additionally, small amounts of other elements may be present to impart specific characteristics.

The most common copper alloy used in hexagonal bars is known as C2600. It typically consists of approximately 70% copper (Cu) and 30% zinc (Zn) by weight. However, the precise composition may vary slightly depending on the specific requirements of the application.

Mechanical Properties

The mechanical properties of the hexagonal copper alloy hexagonal bar play a vital role in determining its suitability for various applications. These properties include tensile strength, elongation, and other mechanical characteristics.

The tensile strength of the copper alloy hexagonal bar is typically around 350 MPa (megapascals) or 51,000 psi (pounds per square inch). This indicates the maximum amount of tensile stress the material can withstand before breaking or deforming.

The elongation of the copper alloy hexagonal bar is a measure of its ductility, indicating how much it can stretch without fracturing. It is usually around 30%, suggesting that the material can undergo substantial deformation before reaching its breaking point.

Tensile Mechanical Properties

The tensile mechanical properties of the hexagonal copper and brass alloy hexagonal bar determine its behavior under different loading conditions. These properties include yield strength, ultimate tensile strength, and modulus of elasticity.

The yield strength is the stress at which the material begins to exhibit permanent deformation. For the hexagonal copper and brass alloy hexagonal bar, the yield strength is typically around 280 MPa (40,000 psi). Beyond this point, the material undergoes plastic deformation and will not return to its original shape once the load is removed.

The ultimate tensile strength represents the maximum stress the material can withstand before failure. In the case of the hexagonal copper and brass alloy hexagonal bar, this value is approximately 350 MPa (51,000 psi). Exceeding this stress will lead to fracture or rupture of the material.

The modulus of elasticity, also known as Young's modulus, measures the stiffness of the material. For the hexagonal copper and brass alloy hexagonal bar, this value is typically around 110 GPa (16 x 10^6 psi). A higher modulus of elasticity indicates greater rigidity and resistance to deformation.

C18200 CuCr1 C18160 CuCrZr alloy bronze metal copper hexagonal bar

Hot Work Annealing Temperature

Hot work annealing is a heat treatment process that improves the material's ductility and reduces its hardness. The specific temperature at which hot work annealing is performed can vary depending on the alloy and its desired properties.

For the copper alloy hexagonal bar, the recommended hot work annealing temperature typically ranges from 550°C to 650°C (1022°F to 1202°F). This temperature range allows for the recrystallization of the material, relieving internal stresses and enhancing its machinability.

Anti-Magnetic Properties

The copper alloy hexagonal bar exhibits excellent anti-magnetic properties, making it suitable for various applications where magnetic interference must be minimized. Unlike ferrous metals, such as iron or steel, copper-based alloys are non-magnetic, allowing them to be used in sensitive electronic equipment and other applications where magnetic fields can cause disturbances.

Percentage of Elements

In addition to copper and zinc, the hexagonal copper and brass alloy hexagonal bar may contain small amounts of other elements to enhance specific properties. The exact percentages of these elements can vary depending on the specific alloy and its intended application.

Common alloying elements found in hexagonal copper and brass alloys include lead (Pb), tin (Sn), manganese (Mn), nickel (Ni), iron (Fe), and silicon (Si). The percentage of each element depends on the specific alloy and can range from trace amounts to a few percentage points.

Uses and Applications

The copper alloy hexagonal bar finds application in various industries due to its excellent mechanical, electrical, and thermal properties. Some common uses include:

Electrical components: The hexagonal bar is often utilized in the manufacture of electrical connectors, terminals, and other components due to its high electrical conductivity.

Plumbing and fittings: Hexagonal bars are commonly used in plumbing applications, such as pipe fittings, due to their resistance to corrosion and ease of fabrication.

Hardware and fasteners: The material's strength and durability make it suitable for various hardware and fastening applications, including screws, bolts, and nuts.

Decorative applications: The copper alloy hexagonal bar's aesthetic appeal and corrosion resistance make it a popular choice for decorative purposes, such as architectural accents, art installations, and jewelry.

Weight and Dimensions

The weight and dimensions of the copper alloy hexagonal bar can vary depending on the specific requirements of the application. Manufacturers offer a range of sizes to cater to different needs. The weight of the bar can be calculated by multiplying its volume by the density of the specific alloy used.